Bundeswehr introduces Leopard 2A7V into service

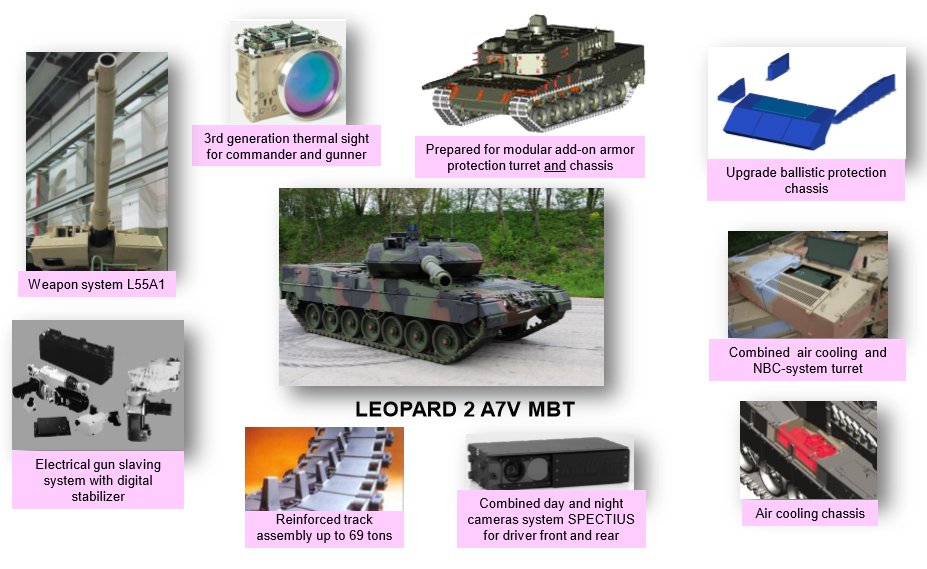

The German Army has introduced the latest variant of its Leopard 2 main battle tank (MBT), the Leopard 2A7V (V for “verbessert“, i.e. improved) into service. The first four tanks were officially handed over during a ceremony on the 15th September 2021 to the Panzerbataillon (PzBtl) 393 located in Bad Frankenhausen, Germany. The Leopard 2A7V features improvements in lethality, mobility and protection over its direct predecessor, the Leopard 2A7 main battle tank. 32 further Leopard 2A7Vs are scheduled to be handed over to the PzBtl 393 in 2021.

The Leopard 2A7V was originally ordered in May of 2015, when it was decided that all of the 20 existing Leopard 2A7, 16 Leopard 2A6, and 68 old Leopard 2A4 tanks – which previously had been owned by the German industry and were (re)purchased by the German government – will be upgraded to the new Leopard 2A7V configuration. Germany has committed to provide NATO’s Very High Readiness Joint Task Force (VJTF) 2023 with thirty Leopard 2A7V main battle tanks, all of which will be operational with the Panzerbataillon 393.

L/55A1 barrels being manufactured by Rheinmetall

Partly assembled Rh 120 L/55A1 gun

L/44 and L/55 guns

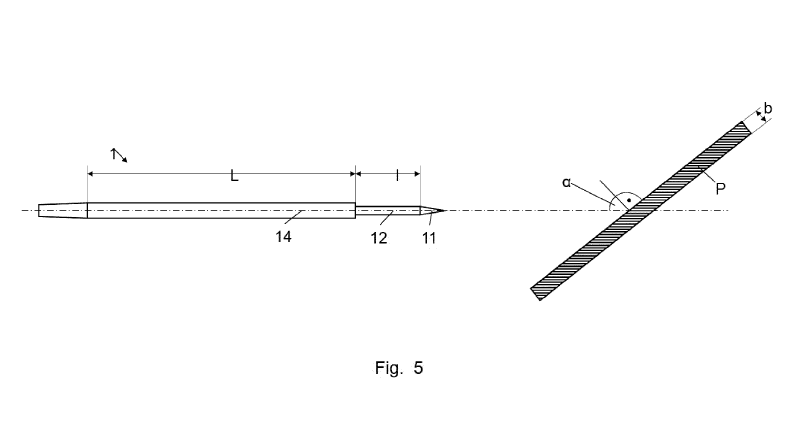

One of the Leopard 2A7V’s key improvements is the Rh 120 L/55A1 smoothbore gun made by Rheinmetall. Like the previous L/55 variant, the new model features a 55 calibre long barrel, i.e. it is about 1.32 metres longer than the barrel of the original Rh 120 L/44 model as well as its derivates such as the American M256 and M256A1 guns. However the L/55A1 is manufactured from higher strength steel grades, made possible thanks to decades of advancements in metallurgy. Hence the L/55A1 can support higher pressures levels and therefore fire more powerful kinetic energy (KE) ammunition. According to the EDR Magazine, the Extreme Service Condition Pressure of the L/55A1 has been raised from 672 to 700 MPa, the Permissible Maximum Pressure to 735 MPa and the Design Pressure to 760 MPa.

In a first step, the 120 mm DM73 APFSDS-T round will be introduced into service with the German Army. It was previously known as the DM63+ and combines the existing penetrator and sabot design of the 120 mm DM63 APFSDS-T round with a new propulsion system that generates a higher chamber pressure. According to figures released by Rheinmetall, this results in a performance uplift by ca. eight percent compared to the existing DM63(A1) APFSDS round. In a second step, a completely new round currently under development under the project name “KE 2020 Neo” will be adopted, which is utilizing a high pressure propellant charge, a new penetrator design and a lightweight sabot.

Exact specifications of the KE 2020 Neo have not been revealed, but Rheinmetall targets a 20% performance uplift. In 2017, the Polish ZBiAM reported that Rheinmetall was working on prototype APFSDS rounds with a 760 mm long penetrator (compared to ca. 680 mm for the DM63 round) and a weight of 10 kilograms including sabot, i.e. ca. 1.25 kilograms heavier than the DM63 round with sabot. Due to the increased weight, the muzzle velocity dropped to ca. 1,670 m/s when fired from the L/55A1 gun; however measures to reduce the sabot weight by 1.1 to 1.3 kilograms and thus increasing muzzle velocity by 110 to 130 m/s were investigated, just like more complex, non-homogenous penetrator designs. In the past years Rheinmetall patented a number of options to increase penetrator length, improve anti-armor performance or increase after-armor effects of APFSDS penetrators. These options include penetrators with variable diameter, intended breaking points, exchangable tips to maximize performance against a certain types of threats and composite penetrators including parts made of tungsten-carbide or other materials.

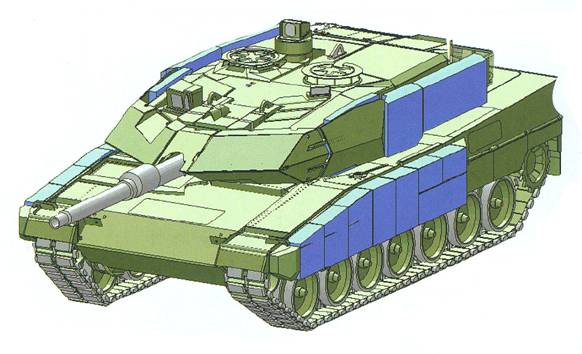

Compared to the earlier Leopard 2A7 tank, the new Leopard 2A7V features improved armor protection. The hull front has finally been fitted with an add-on armor module. Such a solution was already developed during the 1990s for the Leopard 2A5, but never adopted on German tanks – originally the adoption of hull add-on armor was planned for 2008 as part of the third stage of the Kampfwertsteigerung (KWS) Leopard 2 program, but this was canceled without replacement. The original armor solution was developed by Ingenieurbüro Deisenroth (IBD, Engineering Office Deisenroth) and marketed as part of the MEXAS (Modular Expandable Armor System) product family. The add-on armor for the Leopard 2A7V is produced in Greece by EODH (Engineering Office Deisenroth Hellas), a Greek subsidiary of IBD that became independent some years ago.

With the hull add-on armor, the Leopard 2A7V’s frontal hull is claimed to reach the same protection level as the frontal turret, i.e. being protected against most types of modern anti-tank guided missiles (ATGMs), large caliber KE penetrators and rocket-propelled grenades (RPGs). The internal armor arrays in hull and turret have been replaced with a more modern solution. Mostly as result of the improved protection, the combat weight of the tank has reached 66.5 metric tons (73.3 short tons). The chassis is rated for MLC 76, i.e. 68.9 metric tons, though the hull itself is supposedly qualified for a gross vehicle weight of up to 70 metric tons.

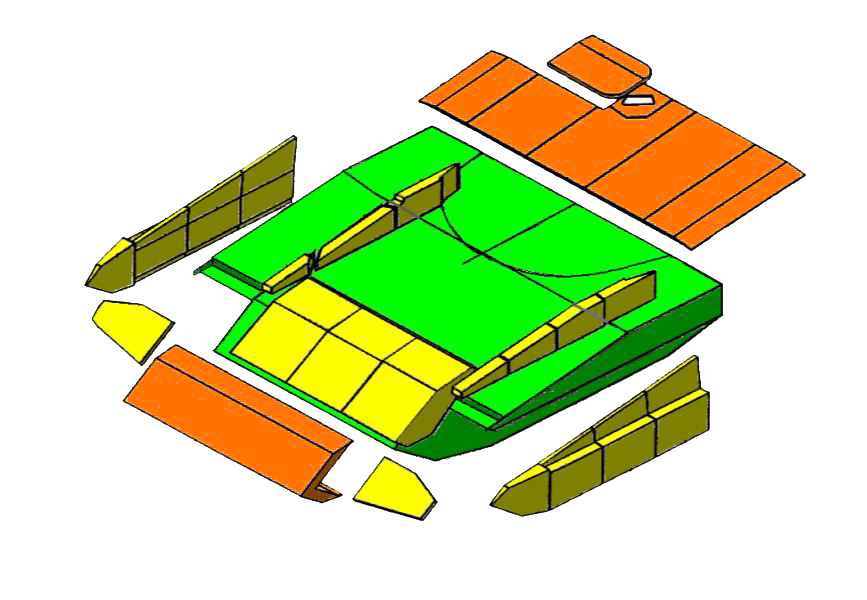

Leopard 2A7 with add-on armor

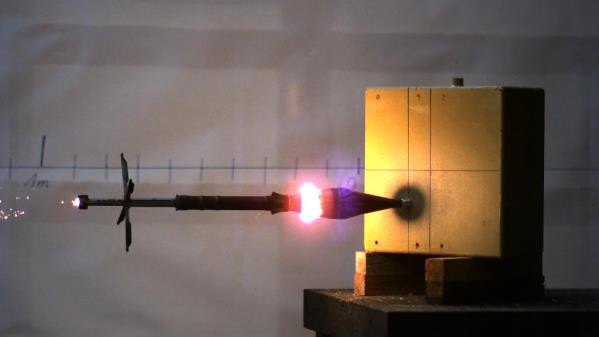

KMW’s NERA solution being hit by a RPG-7

As the Leopard 2A7V is based on the Leopard 2A7 design, it features interfaces for the adaption of further add-on armor modules covering the flanks of hull and turret. KMW has developed an armor kit for urban combat and peace-support operations (PSO) that protects these areas against RPGs. This modular armor solution consists of Beulblechpanzerung (bulging plate armor, i.e. a type of NERA) mounted in large boxes along the hull and turret, as well as a “RPG catcher”, which is an additional armor plating mounted to the side of the hull meant to defeat the tip of an incoming shaped charge jet. This add-on armor is understood to be known under the name “Panzerung in E-Technologie” and was originally developed for KMW’s privately-funded PSO. It was later adopted on the Canadian Leopard 2A4M CAN tank and on the German Leguan 2 bridge-layer, but has yet to be fitted to a Bunderswehr Leopard 2A7(V) tank. In addition to this passive armor, the Leopard 2A6M tank introduced a mine protection kit against large anti-tank mines and IEDs (including those with EFP warhead) and the option to mount additional armor plating at the lowermost section of the hull.

To deal with the increased combat weight, the final drives of the Leopard 2A7V have been modified; i.e. the gear ratio was altered in order to increase acceleration at the expense of top speed. The tank’s top speed is reportedly down to only 63 kilometres per hour, but the acceleration behaviour has improved compared to some of the heavier earlier models such as the Leopard 2A6M and 2A7 tanks. The transmission was hardened, so that it can deal with the higher weight without sacrificing component lifetime. The MB 873 multi-fuel capable diesel engines of the Leopard 2A7V tanks have received a general overhaul and are prepared for an uprating as part of a future upgrade.

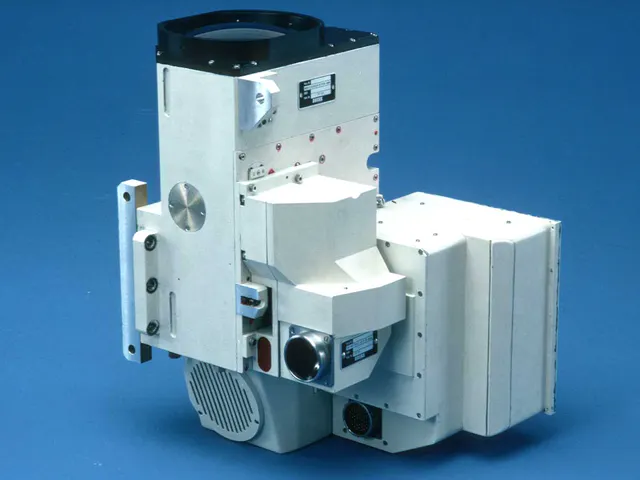

WBG-X first generation thermal imager

Photo: Zeiss

ATTICA third generation thermal imager

Photo: Zeiss

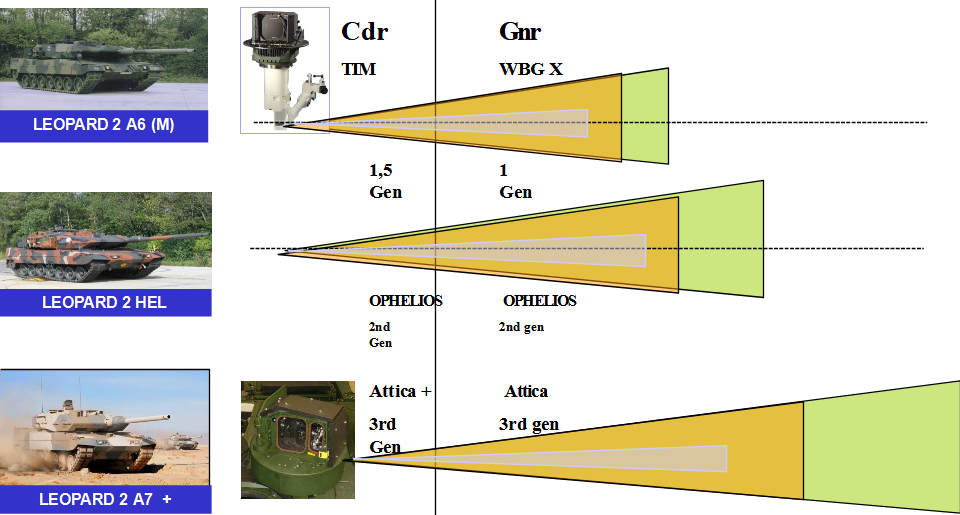

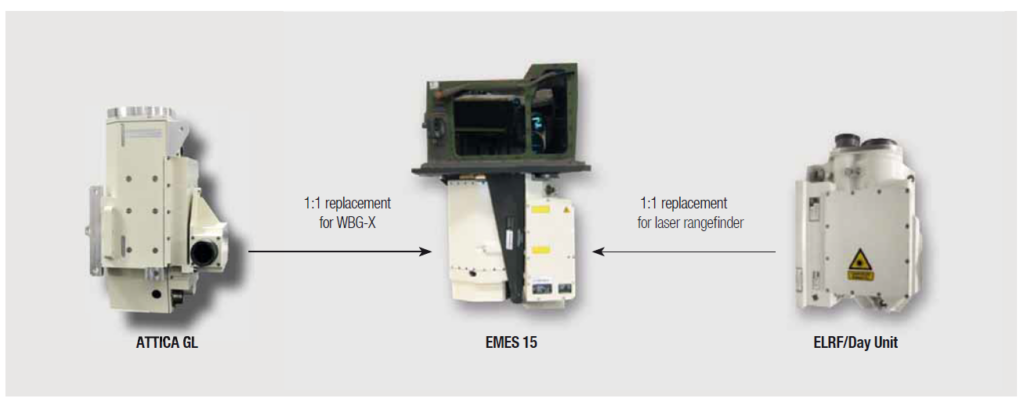

The gunner of the Leopard 2A7V is provided with the new ATTICA-GL (gunner Leopard) thermal imager as part of his upgraded EMES 15 sight, while the commander has access to a ATTICA-Z thermal imager mounted in his PERI R17A3 sight. Both of these thermal imagers are made by Hensoldt and are based around the same MCT focal plane array consisting of 640 by 512 detector elements. For the Leopard 2, Krauss-Maffei Wegmann has selected a system operating in the longwave IR (LWIR) spectrum (i.e. 8 to 12 µm) rather than the midwave IR (MWIR) or shortwave IR (SWIR) spectrums, as this is better suited for the humid European environments.

Compared to the WBG-X first generation thermal imager (with a single line of 120 detector elements), the new ATTICA thermal imagers provide greatly increased recognition, detection and identification distances. The Hensoldt BAA II sight featuring the MWIR version of ATTICA (with a 640 by 512 detector focal plane array) can detect NATO targets at 15.7 kilometres, recognize them at 9.3 kilometres and identify them at 4.8 kilometres using the BAA II’s super near field-of-view (SNFOV). The BAA II features greater magnification levels than the Leopard 2A7V’s EMES 15 gunner’s sight and PERI R17A3 commnader’s sight, hence the Leopard 2A7V is understood to have shorter detection, recognition and identification distances. However according to KMW, the ATTICA thermal imager allows detecting targets at ranges beyond the main gun’s effective combat range.

In order to improve the night-driving ability of the Leopard 2A7V, the Hensoldt SPECTUS (Spectral Technologies for Unlimited Sight) II or III optic has been installed at the “nose” of the hull. It includes a thermal imaging system with an image intensifier; using software the output of both these systems can be fused for improved clarity/contrast. The improved rear drive camera also includes a thermal imager.

The Leopard 2A7V also features a new air conditioning system; while its direct predecessor already introduced a powerful air conditioning system, a newer one has become available on the market (between the development of the Leopard 2A7 and 2A7V main battle tank) that can double-act as NBC protection system and fits within the existing power envelope and space. The old NBC protection system has been turned into an additional air conditioning system specifically meant for the driver. The APU of the Leopard 2A7V has been upgraded to provide a power output of 20 instead of only 17 kilowatts in order to support both air conditioning systems as well as all other electrical systems of the tank.

The upgrade will also introduce a number of minor modifications and include obsolescence removal on certain components. The fitting of the Barracuda Mobile Camouflage System (MCS) from SAAB has to be altered for the Leopard 2A7V in order to correspond to the altered shape of the hull and turret. The electric drive system for the gun stabilization has been improved and the old monitor for the tank commander has been replaced by a current model. The headsets for the crew’s communication system are now worn with a helmet-like hard casing rather than above the beret.

Leopard 2A6(M)A3/A4 and Leopard 2A7A1

At the current point of time, only 104 tanks will be upgraded to the Leopard 2A7V standard; however 101 older Leopard 2A6(M) tanks will undergo a limited upgrade to the Leopard 2A6(M)A3 (or A4) standard featuring improvements to the controls & displays, new communication systems, the SPECTUS II driver’s sight, fire control system and optics. It is believed that these tanks will also receive the ATTICA (advanced two-dimensional thermal imager with CMOS array) third generation thermal imager, given that spare parts for the old WBG X and the Israeli-made TIM 7-12 are hard to come by. The upgrade also aims at simplifying logistics and bringing the hull up to Leopard 2A7(V) level – at the moment it is not known what this will encompass exactly.

Originally the German Ministry of Defence planned to commit 17 Leopard 2A7(V) tanks equipped an active protection system (APS) to the VJTF 2023. The Rafael Trophy APS was selected – based on system maturity rather than performance during firing trials – and the system was integrated into a demonstrator by KMW. However delays in the procurement, integration and/or qualification process has lead to the Trophy-equipped main battle tanks – designed Leopard 2A7A1 – not becoming available before 2024. Hence the decision was made to instead provide the VJTF 2023 with 30 Leopard 2A7V tanks.

The Leopard 2A7A1 is therefore created by upgrading older Leopard 2A6A3 tanks, as this ensures the availability of the 2A7V tanks for NATO’s Very High Readiness Joint Task Force. The turrets of the Leopard 2A6A3 are fitted with the Trophy APS in what seems to be add-on modules for the turret bustle and then mated with newly produced hulls. Given that the Leopard 2A6 hull has no APU and the old tank’s electrical systems are insufficient for handling the high power demand of an APS, these hulls are made from scratch. Images from KMW suggest that the Leopard 2A7A1 will features the SPECTUS II driver’s sight, but not the frontal hull add-on armor module fielded on the Leopard 2A7V; instead the uppermost area of the hull front will be fitted with a light-weight add-on armor system to stop RPGs; the same armor is also used on the Leopard 2A4M CAN and was fielded on the Canadian Leopard 2A6M tanks during their Afghanistan deployment.

At the moment it remains unknown whether the fact that 17 Leopard 2A6A3 turrets will be used for the creation of the Leopard 2A7A1 means that only 84 Leopard 2A6(M)A3 tanks will be procured.

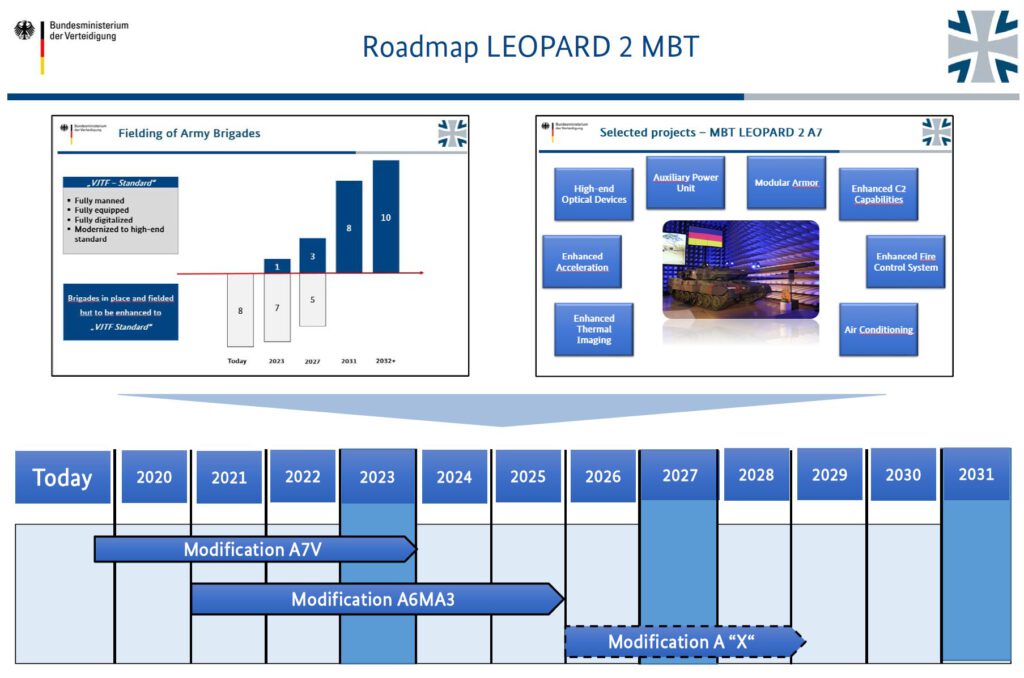

Future improvements

While the Leopard 2A7V is a major step-up in the combat capabilities of the German Army’s Leopard 2 main battle tank, the Bundeswehr still plans a further upgrade before a next generation main battle tank will be fielded as part of the Main Ground Combat System (MGCS) program. Under the code name “Leopard 2AX” a further improved Leopard 2 variant is being developed with the goal to replace all existing models of the Leopard 2 main battle tank in the Bundeswehr. The German Ministry of Defence is planning with the start of this upgrade in 2026.

The exact scope of the Leopard 2AX upgrade is yet to be released; it is likely still being defined. However the German Army already has released a “wishlist”, i.e. in an article for the German defence magazine ESuT, OTL Frank Lobitz – deputy project manager for the Leopard 2 project at the German military procurement office BAAINBw – mentioned a number of desired features:

- a remotely controlled weapon station (RWS), most likely a FLW 200 mounted ontop of the turret

- a hardkill active protection system

- a more powerful 1,200 kW (1,610 hp) engine

- upgrades to the FCS such as e.g. an auto-tracker

Meanwhile KMW is also working on improvements to the Leopard 2 design. A key aspect of the company’s work seems to be enhancing the tank’s survivability. As reported by the EDR Magazine, the company is proposing to use new built turrets for the 2AX upgrade, as new material technology and advanced materials would allow to either reduce the turret’s mass while maintaining the current level of protection – or increasing the protection level at the same weight. KMW also suggest that the optical connection to the gunner’s sight might be replaced, thus only a digital signal would be delivered to the gunner. Germany has accepted a similar set-up on the Puma IFV, where the gunner is provided with an electro-optical targeting system (EOTS) made by Hensoldt. The removal of the optical channel would minimize the weakspots of the turret.

At the same time KMW is considering further survivability enhancements by fitting the tank with electronic countermeasures such as jammers or laser warning receivers (LWRs) providing the Leopard 2 with a limited softkill APS functionality when linked to the multi-spectral smoke grenade dischargers. The adoption of explosive reactive armor (ERA) on the Leopard 2 main battle tank is also considered. In regards to lethality, KMW is considering replacing the gunner’s ATTICA-GL and/or the commander’s ATTICA-Z thermal imagers with the ATTICA M-2 model, which features a higher resolution 1,280 by 1,024 detector element array and thus increases the detection, recognition and identification ranges of potential targets.

The successor of the current commander sight, i.e. the hypothetical PERI R17A4 sight, could receive its own laser rangefinder in order to enhance the hunter-kill capabilities of the Leopard 2AX even further. Further situational awareness systems, a digital vectronics architecture – likely based on STANAG 4754 NATO Generic Vehicle Architecture (NGVA) standard – and the possible integration of external, UAV-based sensor systems is also considered.

Currently KMW already offers the Leopard 2A7+ model, which in many aspects goes beyond what the Leopard 2A7V is capable of. E.g. the Leopard 2A7 QAT – based on the 2A7+ model – already features a FLW 200 RWS and enhanced roof armor capable of protecting against artillery sub-munitions and bomblets. It also featured an upgraded FCS: the commander of the Leopard 2A7 QAT is provided with the PERI Rundumsicht, Tagsichtkanal, Wärmebildgerät, Laserentfernungsmesser (RTWL) sight, which includes an ATTICA-Z thermal imager, an optical channel for daylight and a LDM 38 eyesafe laser rangefinder with a range of 40,000 metres. Furthermore the Leopard 2A7 QAT is fitted with a crosswind sensor mounted on the turret bustle. In a 2012 test campaign in Saudi-Arabia, the Leopard 2A7+ with the improved FCS managed to hit targets in 6,000 metres distance.